Features and applications

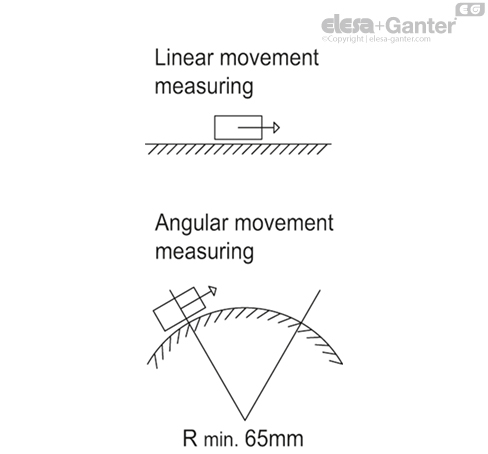

MPI-R10-RF measuring system connected to a specific sensor FC-MPI, combined with the magnetic band M-BAND-10, is a complete system for the measurement of linear and angular displacement (with a minimum radius of 65 mm).

Characterised by an extremely easy assembly, it allows precise alignment and positioning, reducing time and machining procedures to the minimum.

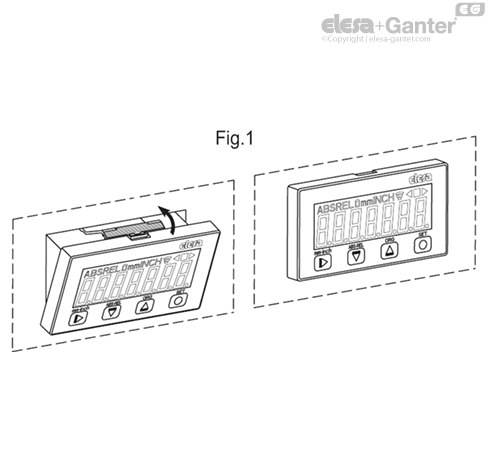

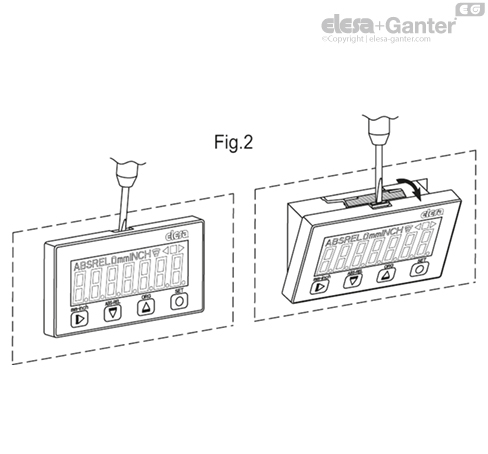

- Maximum ease of assembly and disassembly operations of the device from the panel, thanks to a system with retention wing (ELESA PATENT).

- 7-digit LCD of 12 mm height and special characters.

- Programmable with 4 multifuction keys.

- Values displayed in millimeters, inches or angular degrees.

- Display of absolute or incremental mode.

- Up to 10 programmable offset values.

- Storage and display of 32 target positions.

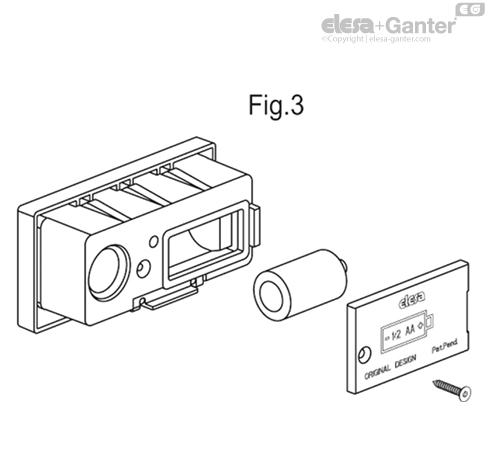

- Long-life internal lithium battery.

- Buffered memory during battery substitution.

- Housing for FC-MPI connector with snap-in assembly system for easy insertion and removal.

For further information read the "Operating instructions".

| Mechanical and electrical characteristics |

|---|

| Power supply | Lithium battery 1/2 AA 3.6 V (included in the supply). |

| Battery life | 2.5 years |

| Display | 7-digit LCD of 12 mm height and special characters. |

| Reading scale | -199999; 999999 |

| Number of decimal digits | programmable |

| Unit of measure | millimeters, inches or angular degrees programmable |

| Max operating speed | 1 ÷ 5 m/s programmable (1) |

| Resolution (2) | 0.01 mm - 0.001 in - 0.01° |

| Precision (3) | ±0.1 mm |

| Repeatability (4) | 0.01 mm |

| Self-diagnostic | Battery check, sensor check, magnetic tape check |

| Protection class | IP54 or IP67 |

| Working temperature | 0 ÷ 50 °C |

| Storing temperature | -20 ÷ +60 °C |

| Relative humidity | Max. 95% at 25°C without condensation |

| Operating environment | Internal use |

| Altitude | Up to 2000 m |

| RF frequencies | 2400-2416MHz |

(1) Reading speed affects battery life.

(2) Resolution: the smallest variation in length that the system is able to display.

(3) Accuracy: the maximum deviation of the value measured by the system with respect to the real value.

(4) Repeatability: the degree of closeness between a measurement series of the same sample, when the individual measurements are made, leaving the measurement conditions unchanged.

Quick positioning system

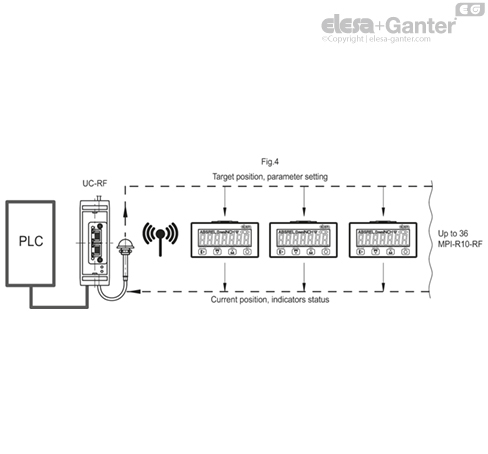

MPI-R10-RF measuring system is networked to the control unit UC-RF via radio frequency (RF), constituting a wireless system for the rapid positioning of machine parts or multi-axial measurements (fig.4).

The wireless connection allows:

- reading of the current position

- setting of the target position

- configuration of all operational parameters

The radio frequency system network allows different machines to coexist in the same space without problems of mutual interference.

This system is particularly suitable for applications that require frequent format changes, facilitating the correct adjustment of the target/current position of the machine parts, also representing a safety system. In fact, even if a single MPI-R10 measuring system is not placed in the target position, PLC doesn’t allow the beginning of the machine production cycle, thus avoiding production issues.

The installation of the system is quick and easy as it does not require the use of connecting cables between the control unit and the indicators.

Further technical information available in "Operating instructions".