GN 817.7

Types

- Type D: Pneumatically double-acting, protrude / retract

- Type A: Pneumatically single-acting, retract by spring force

- Type E: Pneumatically single-acting, protrude by spring force

Coding

- OP: Without position query

- BS0,4: Position query on both sides, with plug, cable 0.4 m

Stainless steel AISI 303

Plunger pin surface hardened

Rod seal

Polyurethane PUR

Piston seal and O-ring

Acrylonitrile butadiene rubber (NBR)

Magnet

Neodymium, iron, boron (NdFeB)

Sensor

- Housing

Polyamide (PA), black

- Cable and plug

Outer sheath polyurethane (PUR), black

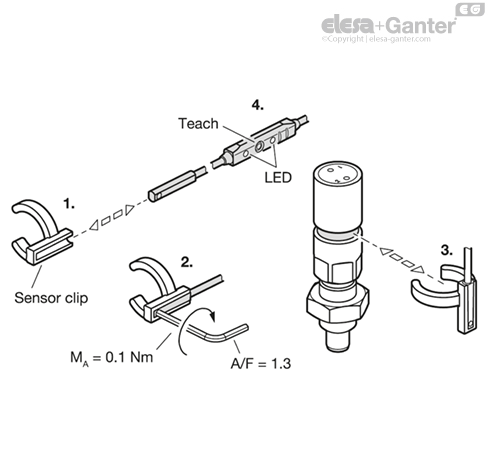

Sensor clip

Polyacetal (POM), black

Lock nut ISO 8675

Stainless steel, AISI 304

LOOKING FOR SOMETHING:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.