DD51-E-RF

Electronic position indicators

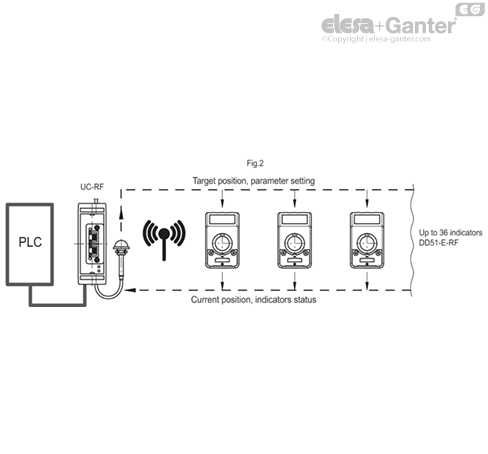

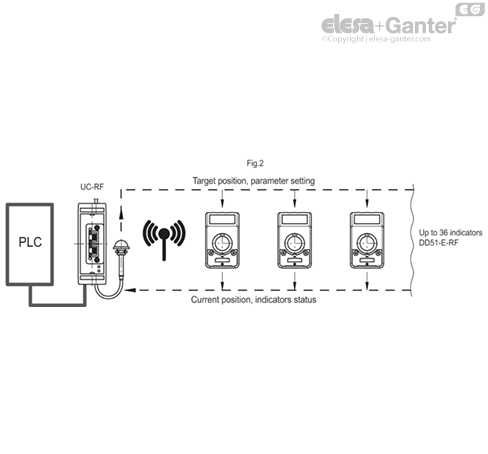

Data transmission by radio frequency

DD51-E-RF

Electronic position indicators

Electronic position indicators

DD51-E-RF

Electronic position indicators

Electronic position indicators

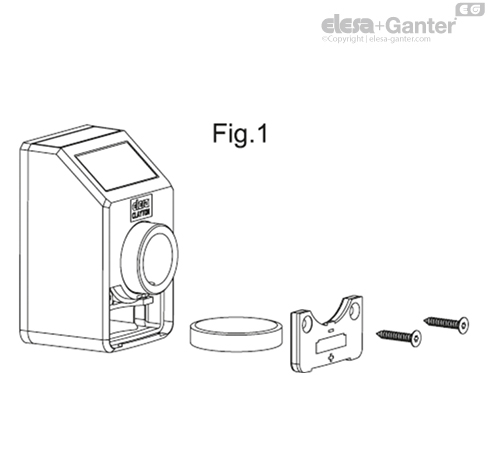

Base and case

High-resistance polyamide based (PA) technopolymer.

Black base.

Case in the following colours:

- C1: RAL 7021 grey-black, glossy finish.

- C2: RAL 2004 orange, glossy finish.

- C3: RAL 7035 grey, glossy finish.

- C55: RAL 5005 blue, glossy finish.

Cover with perfectly sealed gasket and AISI 304 stainless steel UNI 6955 type self-tapping screws with six-lobe socket TORX®T06 (registered trademark by TEXTRON INC.).

The bonding between the base and the containment case using a high-performance sealant, in addition to preventing the penetration of dust and liquids, prevents them from detaching during use.

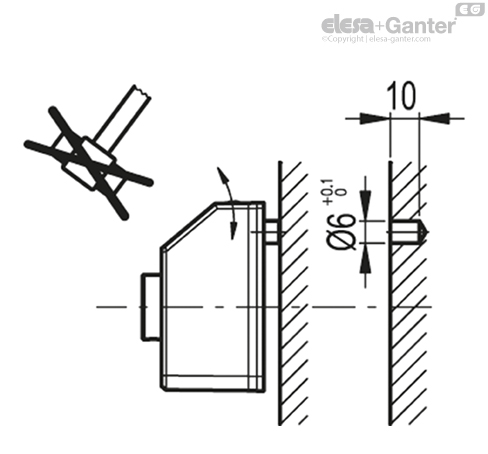

Boss

AISI 304 stainless steel with Ø 14 mm H7 reamed hole, fitting to shaft by means of AISI 304 stainless steel grub screw, hexagon socket and cup end UNI 5929-85, included in the supply.

Window

Transparent polyamide based (PA-T) technopolymer, moulded over the case and with a perfect seal. Resistant to solvents, oils, greases and other chemical agents (avoid contact with alcohol during cleaning operations).

Display

- 5-digit LCD of 8 mm height and special characters.

The visualization parameters can be set and modified by the operator by means of appropriate keys:

- values displayed in mm, inches or degrees

- display of mode for use (absolute or incremental mode)

- reading orientation (right or reverse).

Keyboard

Polyester membrane. Resistant to solvents, alcohol, acids, alkalis.

Internal gasket

O-ring front sealing in NBR synthetic rubber, between the case and the boss.

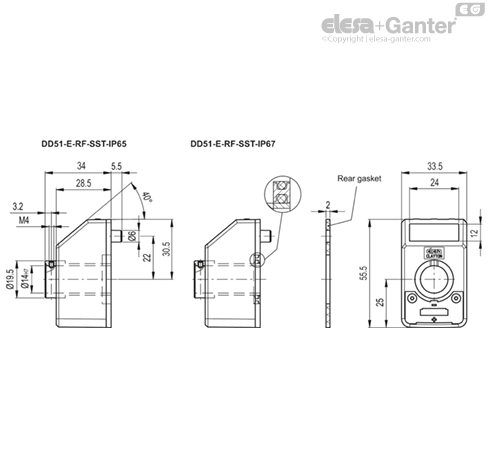

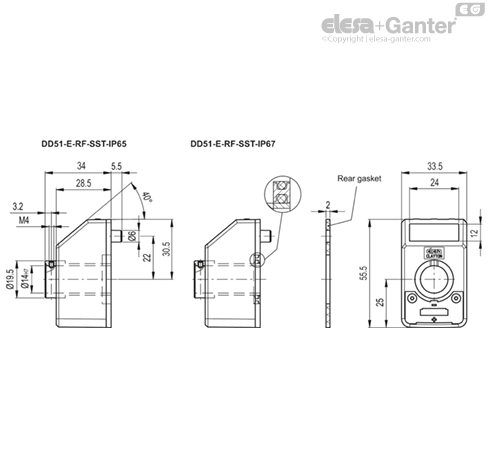

Brass bushing with double O-ring sealing in NBR synthetic rubber inside the rear cavity of the base (DD51-E-RF-SST-IP67).

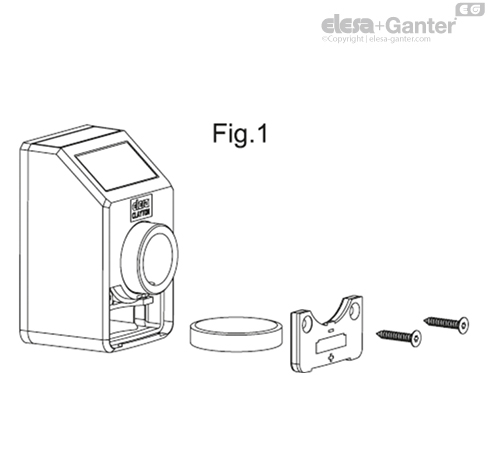

Rear gasket

Foam polyethylene, supplied.

Standard executions

- DD51-E-RF-SST-IP65: completely sealed indicator with IP 65 protection class, see EN 60529 table.

- DD51-E-RF-SST-IP67: completely sealed indicator with IP 67 protection class, see EN 60529 table obtained by means of a brass bushing with double seal ring inside the rear cavity of the base.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.