GN 1582

Stainless Steel Screws

Hygienic Design, Low-Profile Head, with Recessed Stud for Loss Protection

GN 1582

Stainless Steel Screws

Stainless Steel Screws

GN 1582-E

Stainless Steel Screws

with EPDM Sealing ring

GN 1582-H

Stainless Steel Screws

with H-NBR Sealing ring

GN 1582

Stainless Steel Screws

Stainless Steel Screws

Stainless steel

- AISI 316 L

- Matte (Ra < 0.8 µm) MT

- Polished (Ra < 0.8 μm) PL

Sealing ring

H-NBR H

Temperature resistant -25 °C to +150 °C

EPDM E

Temperature resistant -40 °C to +120 °C

- Blue

- Hardness 85±5 Shore A

- FDA compliant

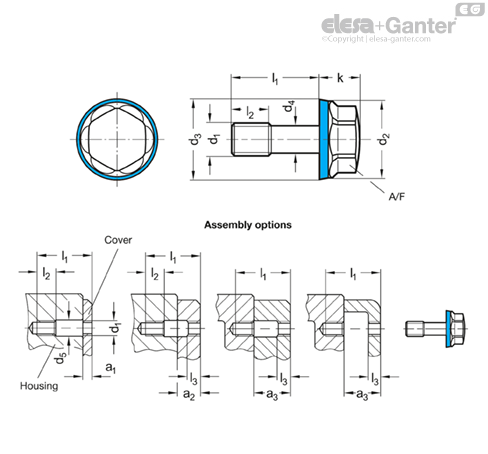

Stainless steel screws GN 1582 with low-profile head are ideal for use in hygienic areas. Due to the d4 recessed stud, they are easily secured against loss, such as in a cover. Thus the „captivity of the mounting element“ according to the Machinery Directive 2006 / 42 / EG is given.

When using, instead of a typical tapped and bore hole, it is necessary to provide tapped bores with a thread d1 on each of the two elements to be assembled. Additionally, a clearance bore of d5 on one or both sides must be cut. Depending on the design and required clamping length a1 ... a3 of the component being attached, there are a number of assembly options as shown above. Alternatively, securing can also be achieved by an additional lock washer mounted on the thin shank d4.

- Screws with additional lock washer (Identification no. 2)

Hygienic Design

Maximum hygiene is a fundamental requirement, not only where food is produced. Hygiene also plays an increasing role in other industrial areas, from the pharmaceutical industry to the manufacture of paints and dyes. Nowadays a major issue is the manufacture of products without added preservatives or with as few added preservatives as possible - while still achieving a long shelf life. However, this can only be achieved in a production environment in which all risks of contamination with microorganisms or dirt are excluded. For plant construction, this means that all components, elements, as well as surfaces, must be designed accordingly. Contaminants must not accumulate and must be easy to remove.

Elesa+Ganter has solutions

Since even the smallest weak spots can contaminate entire production lines, Elesa+Ganter decided to develop a special series of Standard Parts that meet the high requirements of the EHEDG and the 3-A Sanitary Standards, Inc.

The Hygienic Design product family

All Standard Parts of the “Hygienic Design” product family are labeled with the HD icon. They combine high surface quality, freedom from dead spaces, non-scooped outer surfaces, and sealed bolting areas. A sealing concept based on FEM calculations ensures reliable contact pressure after installation. Hygienic Design also means that the time and material needed for regular cleaning is significantly reduced - which also noticeably lowers operating costs.

Why Hygienic Design?

In the food industry, medical technology and the pharmaceutical industry, product safety and consumer protection are becoming increasingly important. Due to their specific properties, standard parts in hygienic design can support the production process in these sensitive areas and facilitate the manufacture of products with a long shelf life, reducing the need for preservative agents.

Advantages of Hygienic Design

Less and shorter cleaning work (this can be up to 25% of the production time), therefore

- more time available for production

- less fresh water consumption

- lower energy consumption

- less cleaning agent required

- less production of waste water

- lower total costs and saving of resources

Legal basis of Hygienic Design

EN 1672-2:2009 “Food machinery”

Machines must be able to be cleaned, i.e. they must be designed and constructed so that dirt can be removed with the recommended cleaning methods.

Machinery directive 2006/42/EC

Machines must be designed so that

- materials can be easily and fully cleaned before each use and

- no risk of infections or illness is created.

DIN EN ISO 14519:2008-07

Hygiene requirements for the design of machines

DIN EN 1672:2009-07

Food machinery – General design principles – Part 2

Design requirements for Hygienic Design

Material

- Non-rusting Stainless Steels

- FDA and EU compliant plastics and elastomers

Surfaces

- Surfaces must be able to be cleaned

- Steps due to appliance configurations which are not aligned must be avoided

- Seals must be designed so that no gaps occur

- O-ring grooves must be hygienically designed

- Contact with the product to be manufactured must be ruled out

- Corners should preferably have a radius of 6 mm or more

Design / Geometry

The interior and exterior areas of all appliances, components or piping must be self-draining or be able to be drained and easy to clean.

Surface properties and roughness

Easy to clean with Ra < 0.8 μm

Design principles for Hygienic Design

EHEDG

- European Hygienic Engineering & Design Group

- non-profit European consortium of machine and food manufacturers as well their suppliers, research institutes, universities and government health agencies

- approximately 45 guidelines

- examination of products and issue of certificates

3-A Sanitary Standard, Inc.

- non profit and independent association in the USA

- three interest groups:public and governmental health agencies, machine and food manufacturers

- over 70 Sanitary Standards

- examination of designs and processes, issue of certificates

Seals

For the standard parts which are listed in Hygienic Design, seals have the central function of protecting dead spaces, gaps and cracks from the penetration of cleaning fluids or product residues.

For this, a defined pre-tension or pressing of the seals and wipers is necessary for a reliable and permanent seal in the installed condition. Within the Hygienic Design product family, seal installation spaces and seal cross sections are calculated and designed with simulation software, so that the necessary surface compression is achieved on installation and the seal material is not subjected to excess pressure.

A fundamental differentiation can be made between static and moving seals:

During assembly, the static seals in the design example shown below are tightened to the mounting surface at the top (sealing ring) and to the contact surface at the bottom (bottom seal). It should be ensured that all surfaces which make contact with the seal have a surface finish of at least Ra 0.8 µm.

The moving seals on the adjustable sleeve (wiper) and the ball joint (joint sealing ring) of the foot are designed so that they allow adjustment in both height and angle. With these too, the installation space together with the cross section of the seal ensures a gap-free, pre-tensioned seal.

Depending on the version and the type of use, it may be the case that seals may need to be replaced in case of damage or for preventative maintenance. For this, Elesa+Ganter supplies the relevant seals as spare parts or offers these under GN 7600 as standard parts for spare parts.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.