GN 115-WSK-SST

Latches

Stainless Steel, Operation with Socket Keys

GN 115-WSK-SST-A4

Latches

Stainless Steel (A4)

GN 115-WSK-SST-NI

Latches

Stainless Steel (NI)

GN 115-WSK-SST-A4

Latches

Stainless Steel (A4)

Version in Stainless Steel (NI)

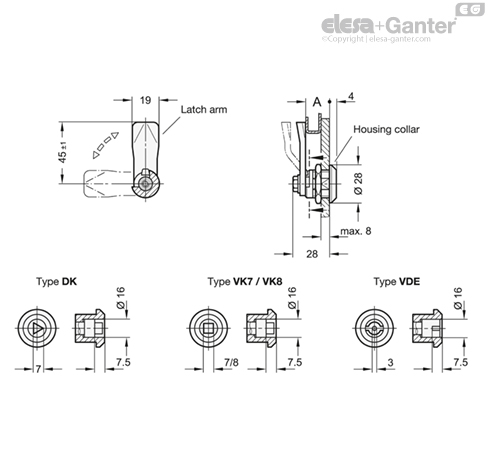

Types

- Type DK: With triangular spindle

- Type VK7: With square spindle

- Type VK8: With square spindle

- Type SCH: With slot

- Type VDE: With double bit

Lock housing

Stainless steel AISI 303 NI

Latch arm

Stainless steel AISI 304

Other parts

Stainless steel AISI 304

Protection class IP 65

Version in Stainless Steel (A4)

Types

- Type DK: With triangular spindle

- Type VK7: With square spindle

- Type VK8: With square spindle

- Type VDE: With double bit

Lock housing

Stainless steel AISI 316Ti A4

Latch arm

Stainless steel AISI 316

Other parts

Stainless steel AISI 316

Protection class IP 66

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.