GN 516.1

Rotary clamping latches

with Continuously Adjustable Latch Distance A

GN 516.1

Rotary clamping latches

Rotary clamping latches

GN 516.1

Rotary clamping latches

Rotary clamping latches

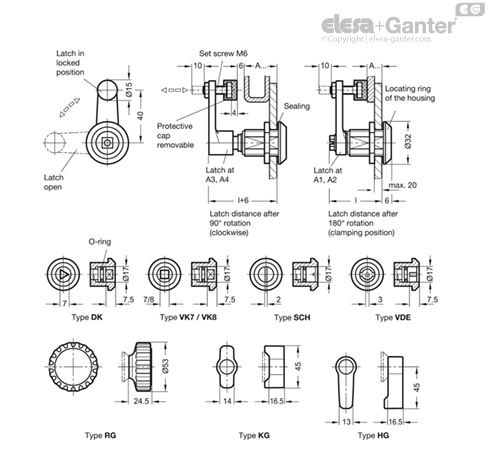

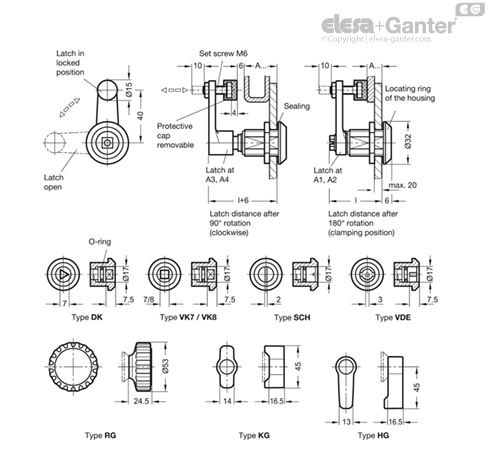

Types

- Type DK: Operation with triangular spindle (DK7)

- Type VK7: Operation with square spindle A/F7

- Type VK8: Operation with square spindle A/F8

- Type SCH: Operation with slot

- Type VDE: Operation with double bit

- Type RG: Operation with knurled knob GN 7336

- Type KG: Operation with wing knob

- Type HG: Operation with lever

Housing / Locking mechanism

Zinc die casting

Locating ring

plastic coated, black, textured finish

Latch

Zinc die casting

all handles (Type RG / KG / HG)

- Plastic (Polyamide PA) black, matt

- Cover cap light grey, matt

Protective cap CR Neoprene©

- 40 to 50 Shore A

- black

Protection class: IP 65

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.