GN 724.2-NI

Spring Latches

Stainless Steel, with Chamfered Pin, with Flange for Surface Mounting

GN 724.2-NI-A1

Spring Latches

Stainless steel, latch arm position perpendicular to the flange, chamfer top

GN 724.2-NI-A2

Spring Latches

Stainless steel, latch arm position perpendicular to the flange, chamfer bottom

GN 724.2-NI-A3

Spring Latches

Stainless steel, latch arm position perpendicular to the flange, chamfer right

GN 724.2-NI-A4

Spring Latches

Stainless steel, latch arm position perpendicular to the flange, chamfer left

GN 724.2-NI-B1

Spring Latches

Stainless steel, latch arm position parallel to the flange, chamfer top

GN 724.2-NI-B2

Spring Latches

Stainless steel, latch arm position parallel to the flange, chamfer bottom

GN 724.2-NI-B3

Spring Latches

Stainless steel, latch arm position parallel to the flange, chamfer right

GN 724.2-NI-B4

Spring Latches

Stainless steel, latch arm position parallel to the flange, chamfer left

GN 724.2-NI-A1

Spring Latches

Stainless steel, latch arm position perpendicular to the flange, chamfer top

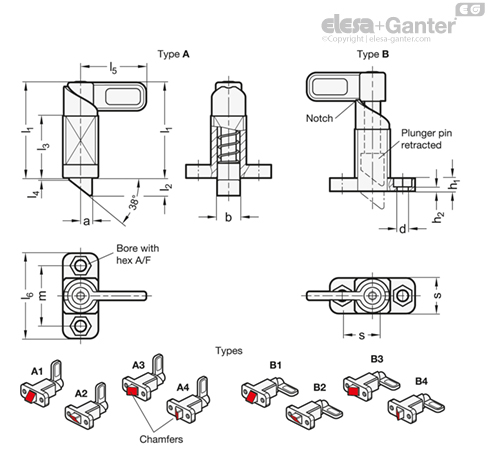

Types

- Type A: Latch arm position perpendicular to the flange

- Type B: Latch arm position parallel to the flange

Identification no.

- No. 1: Chamfer, top

- No. 2: Chamfer, bottom

- No. 3: Chamfer, right

- No. 4: Chamfer, left

Guide

- Stainless steel precision casting AISI CF-8 NI

Latch arm

- Stainless steel precision casting AISI CF-8 for NI

Plunger pin

- Stainless steel AISI 431, hardened for NI

Compression spring

Stainless steel AISI 316Ti

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.