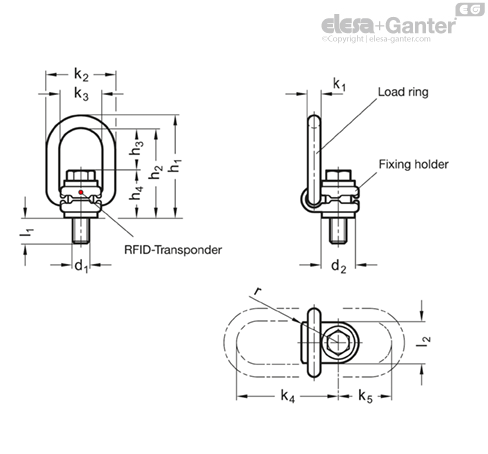

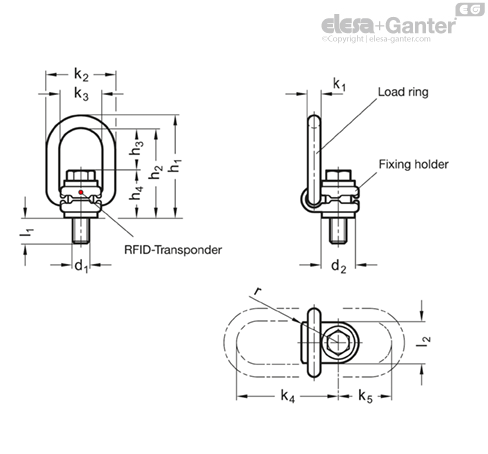

GN 586.1

Load rings (rotating)

GN 586.1

Load rings (rotating)

Load rings (rotating)

GN 586.1

Load rings (rotating)

Load rings (rotating)

Load rings

Steel, German Material No. 1.6541

- forged

- high-tensile tempered

- 100 % electro magnetic tensile tested to EN 1677

- plastic coated, pink

Fixing holder

- forged

- high-tensile tempered

- 100 % electro magnetic tensile tested

- plastic coated, pink

Bolt

Steel, high-tensile tempered

Finish: Delta Tone

Bushing

Steel

galvanic zinc plated

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.