All ball operated conveyers are made up of a number of balls each located in a socket resting on a number of smaller support balls thus allowing the larger ball to rotate in any direction.

Arrangement and choice of ball size

When deciding on the size of the conveyer the following factors have to be taken into account: Weight, size, base material as well as the load to be carried.The

max. distance between the roller balls „a2“ (on a plane surface) is arrived at by dividing the shortest edge length of the load to be conveyed by 2.5. This ensures that a load will always be supported by carrier balls thus preventing it from tipping over into an empty space.The required

load carrying capacity of the balls is determined by the weight of the actual load divided by three. This is arrived at from the assumption that, due to tolerances on the load carrying face and the spacing of the balls in general, only three balls will be under load at any one time.

a1 = shortest edge length of the load F1 = Load weight

a2 = max. distance between roller balls F2 = Load per roller ball

a2 = a1/2.5 F2 = F1/3

Speed and friction

The permissible conveying speed is 2 m/sec. With larger roller balls at speeds exceeding 1 m/sec., depending on the weight being conveyed, an increased temperature would be expected.

The friction values of the balls at a speed of 1 m/sec. will be in the region of 0.005 µ. This value is, however, dependent on application of usage and could be subject to large variations.

In comparison of balls with sheet metal housings (GN 509) with balls in heavy duty steel housing GN 509.1 , the latter have a higher rigidity. Hence the static values of balls in steel housing can be applied.

Lubrication to prevent corrosion is recommended. The general recommendations applicable to ordinary roller bearings will be sufficient. In most applications lubrication can be ignored.

Resistance to temperature

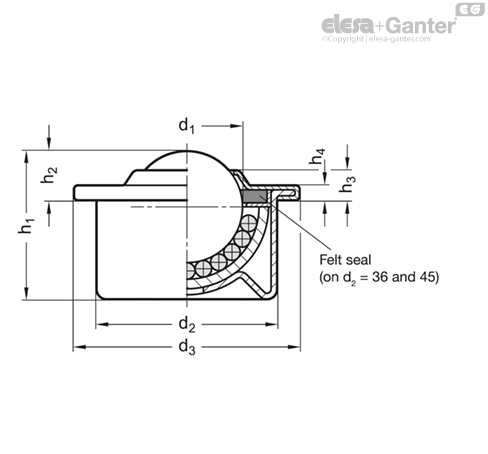

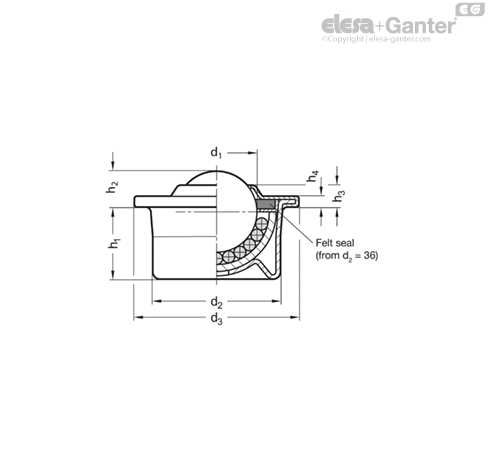

Balls from size 36 upwards are fitted with a felt seal as protection against ingress of dirt and dust. The latter have a max temperature of 100 °C only.

Balls without the felt seal can also be used at higher operating temperatures. This, however, will lead to a reduced conveying capacity (c). The following table gives indicative values:

125 °C ./. 10 %

150 °C ./. 20 %

170 °C ./. 30 %

200 °C ./. 50 %

The max. operating temperatur for ball transfer units with plastic ball is 60 °C.