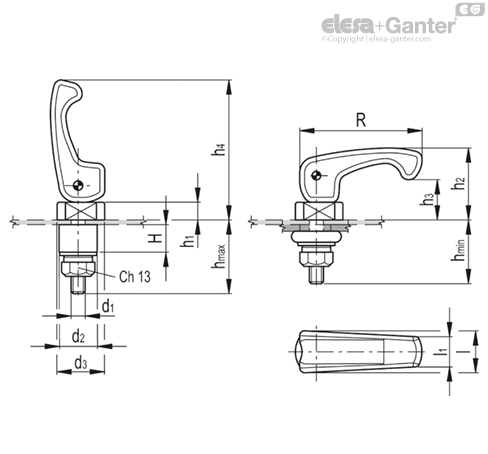

LAC-FL

Cam levers

for quick clamping, technopolymer

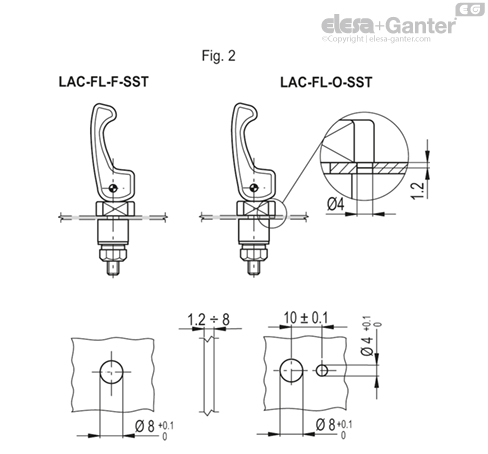

LAC-FL-F-SST

Cam levers

Without anti-rotation reference pin

LAC-FL-O-SST

Cam levers

With anti-rotation reference pin

LAC-FL-F-SST

Cam levers

Without anti-rotation reference pin

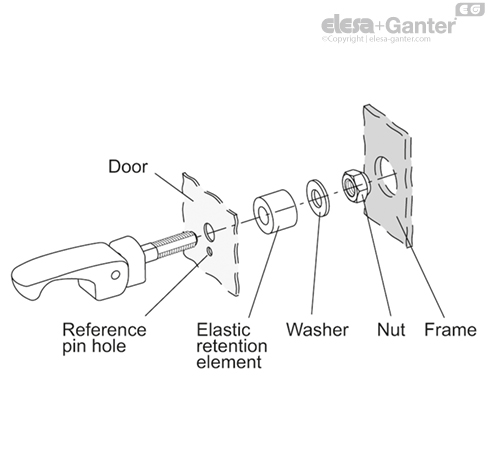

Cam lever body

Glass-fibre reinforced polyamide based (PA) technopolymer, black colour, matte finish.

Elastic connecting pin

AISI 301 stainless steel.

Cam sliding base

Polyamide based (PA) technopolymer, black colour.

Threaded pin

Polyamide-based SUPER-technopolymer (PA), black colour.

Elastic expansion retention element

NBR synthetic rubber, hardness 60, Shore A.

Self-locking nut and washer

AISI 304 stainless steel.

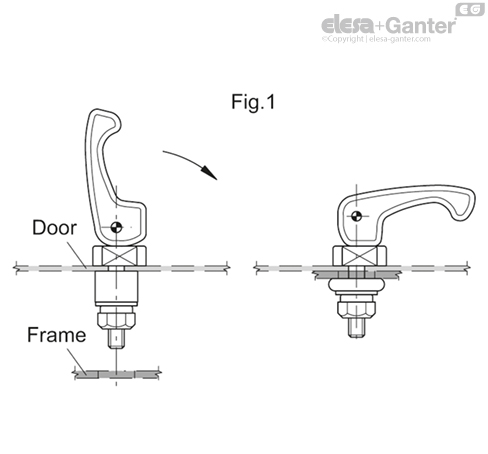

Standard executions

- LAC-FL-F-SST: the lever is free to position itself in any direction.

- LAC-FL-O-SST: the lever is always kept oriented in the desired position thanks to the anti-rotation reference pin.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.