Force details, calculationGeneral information

The eccentric principle has two advantages: A large clamping force Fs and a self-locking mechanism as soon as the dead centre is exceeded.

All theoretical attempts to describe the ratio between manual and clamping force will ultimately rest only on assumptions in some parameters. The actually prevailing conditions are influenced by a number of different factors.

The values given in the tables below are therefore based on practical specifications and findings and rest on test series which have shown which clamping forces can be achieved by applying the specified manual forces.

The maximum permitted pretensioning force of each thread size will not be exceeded by operating the lever.

Clamping and manual forces

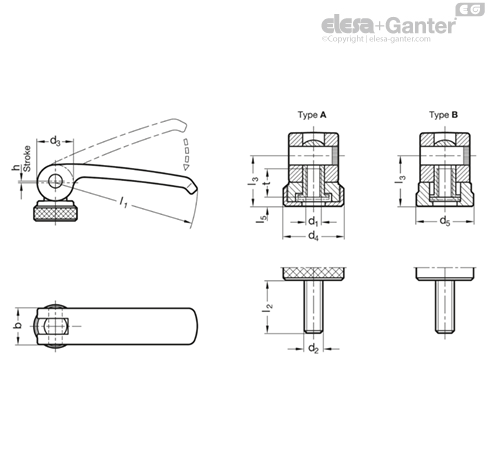

| l1 | ≈ FH | ≈ lH | ≈ FS |

| Lever size | Manual force in N | Lever, manual force | Screw force / Clamping force in N |

| - | - | - | GN 927 / GN 927.4 | GN 927.3 / GN 927.5 | GN 927.2 / GN 927.7 |

| 44 | 75 | 33 | 1250 | 1750 | 1450 |

| 63 | 125 | 47 | 2250 | 3100 | 2600 |

| 82 | 200 | 62 | 3700 | 5000 | 4300 |

| 101 | 350 | 76 | 6100 | 8000 | 7000 |

Calculation

To account for the above theoretical and arithmetical alternative for determining clamping and manual forces, a potential solution will be shown below which will ultimately also prove the plausibility of the values given in the table using a calculation example.

When theoretically determining the clamping force Fs resulting from the manual force, two points must be observed in particular:

First, there are the geometrical conditions existing at the eccentric which call for an arithmetically complex approach if one wishes to take account of the exact conditions. Secondly, the friction occurring at several points will have a strong impact on the achievable clamping force.

1st alternative, eccentric

Looking at the developed view arising in an eccentric through the rolling motion, one will find that this is caused by a sinusoidal curve.

The result is that the gradient angle w above the swivel range changes permanently, causing an extension of the self-locking range and of the force transmission.

However, the arithmetical description of this approach is highly complex.

Substitute calculation model

In simple terms and assuming a constant gradient, the existing sine curve may be seen as a wedge which will result in a sufficiently accurate and approximate substitute calculation model which is a great deal less complex.

A friction value will be assumed for the axis of rotation and the circumference of the eccentric, which will in reality be strongly influenced by external factors and may therefore diverge accordingly.

2nd alternative, eccentric

A 90° motion of the manual lever covers the stroke h.

| Fs | Screw force / clamping force (resulting) |

| Fh | Manual force |

| lH | Lever arm of the manual force |

| FRU | Friction force at circumf. |

| lU | Lever arm at circumference |

| FRA | Friction force at the axis |

| lA | Lever arm at the axis |

| w | Substitute wedge angle |

| h | Stroke at 90° rotation of the lever |

| µ1 | Friction coefficient at circumf. |

| µ2 | Friction coefficient at the axis |

Equations and model calculations

| Clamping force | Friction coefficient (wedge angle, ¼ circle) |

| Fs = FH x lH / ((lU x ( µw + µ1)) + ( lA x µ2)) | µw = h x 4 / π x 2 x lU |

| Example |

| Clamping lever with eccentrical cam GN 927.7-101-M8-B |

| with manual force FH = 350 N, friction coefficient µ1 = 0,2 and µ2 = 0,1 plus lever arm lA = 5 mm and lU =11,5 mm |

| Fs = 350 N x 76 mm /((11,5 mm x (0,083 + 0,2)) + (5 mm x 0,1)) = 7000 N |

| The following friction coefficients µ may be used for potential friction pairings: |

| Plastic / Plastic ≈ 0,25 | Steel / Steel (lubricated) ≈ 0,1 | Steel / Steel ≈ 0,2 |

| Plastic / Steel ≈ 0,15 | Stainless Steel / Stainless Steel (lubricated) ≈ 0,1 | Stainless Steel / Stainless Steel ≈ 0,2 |

Safety notices

The design of applications involving clamping levers with eccentrical cam should always be made including an adequate safety factor. Usual safety actors for static loads 1,2 to 1,5; pulsating 1,8 to 2,4 and alternating 3 to 4. To be increased proportionally in applications with higher safety requirements.

Disclaimer:

The information and recommendations we give are made without commitment and excluding any liability, unless we have committed ourselves expressly and in writing to give such information and recommendations. All products are standard parts designed for a variety of different uses and have as such been subjected to extensive standard tests; users should determine in their own test series, for which we will not be liable, whether a product will be suitable for certain special applications and uses.