Perfectly Positioned with Stainless Steel Adjusting Screws

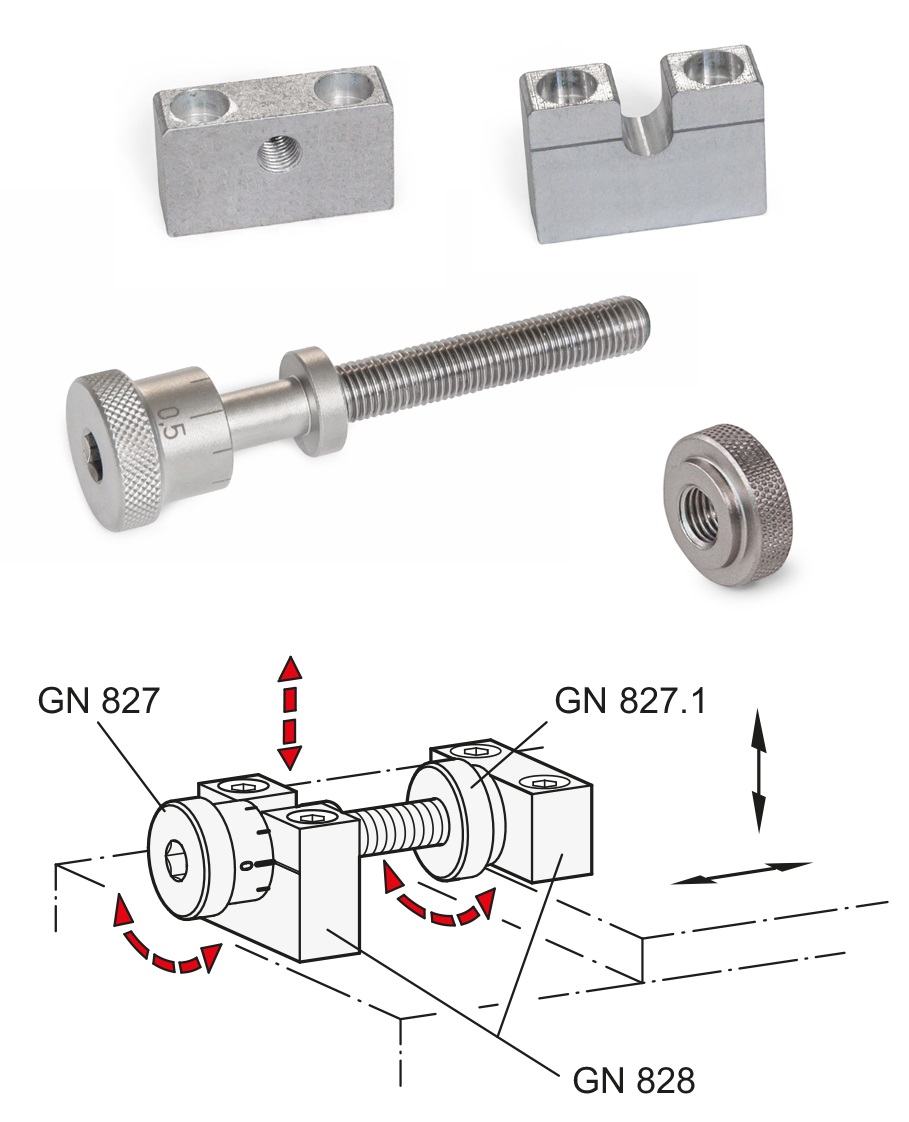

On production machines and mechanisms, it is often necessary to carry out repeated positioning operations as simply and reliably as possible. For such precision and secure and simple adjustment for quick changing of mechanisms or tools, Elesa+Ganter now offers three new parts that complement each other perfectly: stainless steel adjusting screws with an adjustment scale plus matching bearing blocks and knurled nuts.

The innovative stainless steel adjusting screw GN 827 from Elesa+Ganter, the specialist of standard parts, is intended for use with bearing blocks GN 828 and simplifies the attachment of parts to various processing and assembly mechanisms in machines, installations and jigs. This means that processes that require the repeated exchange, repositioning and adjustment of devices can be carried out much more quickly. The mechanisms are moved in or out of position using an adjusting screw with rotating knob and hexagon socket fitted with a scale in 0.1 mm graduations.

Depending upon the application, the stainless steel adjusting screws are available in a variety of thread diameters and lengths, and can be optimally fastened to the production machine in combination with bearing block GN 828 from Elesa+Ganter. Once the optimal setting has been found, the adjusting screw can be locked in place with a stainless steel knurled nut GN 827.1 designed specifically for this purpose. The bearing blocks are made of matte, smoothly polished aluminum and differ in terms of the screw fastening, which can be from above or from the front.

They are optionally available with a female thread matching the adjusting screw or a receiving groove that provides axial support for the adjusting screw. In addition to the scale on the rotating knob, the receiving groove has a laser-engraved reference line for adjusting the device. In particular, this receiving groove facilitates the replacement of devices or tools with the “Single Minute Exchange of Die” method (SMED). Set-up time and costs are reduced to a minimum, and production can continue with the previously set dimensions minimising machine downtime.

More detailed information on this standard Elesa+Ganter part can be found by clicking here.